Conductive high purity silicon carbide powder is a key semiconductor material, known for its excellent physical and chemical properties such as high-temperature stability, high thermal conductivity, high hardness, and superior electrical conductivity. It is widely used in the manufacturing of high-temperature, high-frequency, and high-power electronic devices, including sic 5g applications.

The synthesis methods for high purity silicon carbide powder mainly include solid-phase methods, liquid-phase methods, and vapor-phase methods. As a leading sic powder supplier, our product was prepared by chemical vapor deposition (CVD) by decomposing silicon source and carbon source gas at high temperature. The induction heating industrial applications and sic 5g technologies are among the key areas benefiting from our high-quality silicon carbide powder. The obtained silicon carbide powder has high purity and uniform particle size.

| Morphology | Particle Size Classification | Percentage Of Particle Size | Apparent Density |

| Particle | 5-8# | ≥85% | 1.15-1.35g/cm³ |

| Particle | 8-20# | ≥85% | 1.20-1.40g/cm³ |

| Particle | 20-40# | ≥85% | 1.20-1.40g/cm³ |

| Acicular | 8-20# | ≥85% | 1.00-1.20g/cm³ |

| Acicular | 20-40# | ≥85% | 1.05-1.25g/cm³ |

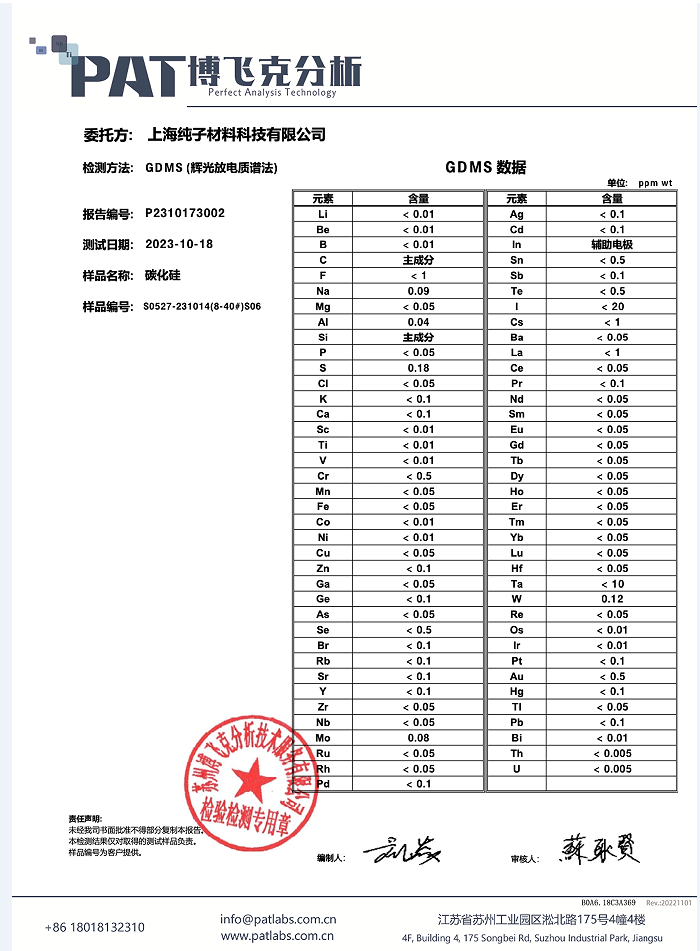

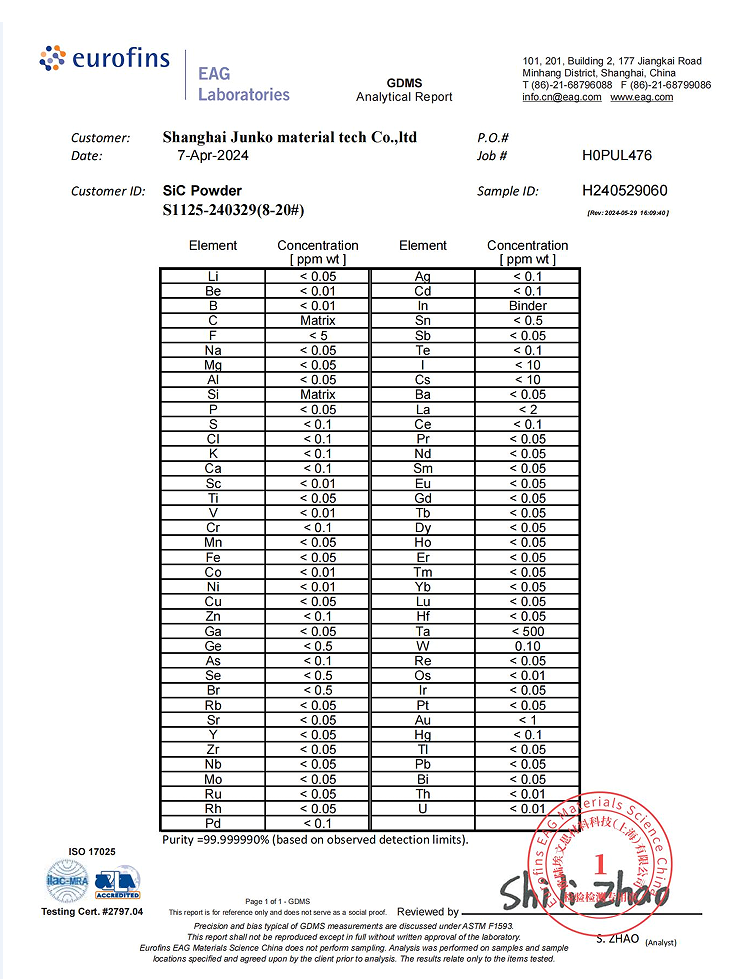

High Purity: 6N5 purity mass production, 7N purity can be done;

Customization: By adjusting the CVD process parameters, it is possible to customize the production of SiC powder with specific properties to meet different application needs.

Particle Uniformity: The particle size of high-purity SiC powder is typically very uniform, which is crucial for manufacturing electronic devices with consistent performance.