Induction brazing is a process that uses electromagnetic induction to heat and join two or more metal components. This method is highly efficient and precise, offering several advantages over traditional brazing methods.

Electromagnetic Induction: In induction brazing, a high-frequency alternating current is passed through an induction coil, creating a magnetic field. This magnetic field induces eddy currents within the metal components, which generate heat due to the resistance of the metal to the flow of the induced currents.

Localized Heating: The heat is generated directly within the metal, allowing for precise control over the heating area and temperature. This is particularly useful for heating specific parts of a workpiece without affecting the entire component.

Material Preparation: The metal components to be brazed are prepared, ensuring they are clean and free of any contaminants that could affect the brazing process.

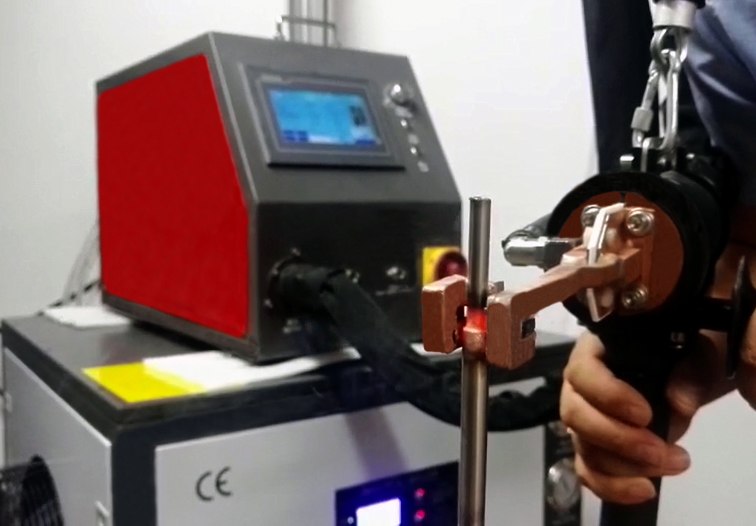

Induction Heating: The components are placed within an induction coil. The coil generates a magnetic field that induces eddy currents in the metal, rapidly heating the components to the brazing temperature.

Brazing: Once the components reach the brazing temperature, a filler metal (brazing alloy) is introduced. The filler metal melts and flows into the joint, creating a strong bond between the components.

Cooling: After the brazing process is complete, the components are cooled to solidify the filler metal and complete the joint.

Post-processing: The brazed joint may undergo additional processes such as inspection, cleaning, or finishing to ensure the quality and integrity of the joint.

Efficient Heating: Induction brazing can achieve rapid and uniform heating, significantly reducing the heating time.

Energy Efficiency: Induction heating is highly energy-efficient, as it directly heats the metal with minimal heat loss.

Precision: The localized heating allows for precise control over the brazing process, reducing the risk of overheating or underheating.

Flexibility: The process can be easily adapted to different shapes and sizes of components, making it suitable for a wide range of applications.

Improved Joint Quality: The rapid heating and cooling rates can result in improved microstructures and mechanical properties of the brazed joints.

High energy density, fast heating speed, significantly improving production efficiency.

It is environmentally friendly and safe, and can work in vacuum or gas protected environments.

For the motor winding, do not damage the insulation.

Easy to achieve automation.

At the same time, the brazing process also puts forward requirements for portable, high power density, and wide matching range of induction brazing power sources. The portable induction heating power supply is most suitable for induction brazing, with a series of portable generators covering 1-360KW. The 40KW handheld generator weighs only 3Kg, and its functions such as fast temperature control, energy control, and fast rhythm operation are particularly suitable for brazing. These products are mainly used in major motor factories, transformer factories, rail electric locomotives, air conditioning refrigerators, compressors and other industries, and have been applied in projects such as Three Gorges hydroelectric generators, steam turbine generators, and wind power generation.

Induction brazing is used in various industries, including automotive, aerospace, electronics, and heavy machinery, where high strength and precision are required.

It is particularly useful for brazing components that are difficult to heat uniformly using conventional methods, such as complex shapes or parts with tight tolerances.

Welding of various hardware cutting tools: welding of diamond cutting tools, grinding tools, drilling tools, alloy saw blades, carbide turning tool, milling cutters, reamers, planers, woodworking drill bits, etc;

Welding of various hardware and mechanical accessories: silver welding and copper welding of the same or different metals, such as hardware bathroom products, refrigeration copper accessories, lighting accessories, precision mold accessories, hardware handles, egg beaters, alloy steel and steel, steel and copper, copper and copper, etc;

Composite pot bottom welding: mainly used for three-layer brazing of round, square, and other heterogeneous flat stainless steel pot bottoms and aluminum sheets, and can also be used for brazing other metal flat surfaces;

Welding of the heating plate of an electric kettle (electric coffee pot): mainly used for brazing between stainless steel flat bottoms, aluminum sheets, and various shapes of electric heating pipes;

Automation induction heating in the refrigeration and HVAC industry: radiators, distributors, air conditioning pipes, heat exchangers, etc.