Induction Heating Products offer precise, energy-efficient heating solutions across industries. With advanced IGBT technology, they ensure uniform heat distribution, rapid response, and superior process control, catering to a wide range of applications from metalworking to semiconductor manufacturing.

Induction Heating Products provide significant environmental benefits, including:

Energy Efficiency & Emission Reduction: They convert electrical energy to heat with minimal loss, reducing energy consumption. As an electric heating method, they eliminate the need for combustion, thereby decreasing emissions.

Sustainability: Promote sustainable manufacturing by offering a clean and efficient heating process.

Material Conservation: Precise heating minimizes material waste, contributing to resource efficiency.

Longevity: Durable design reduces electronic waste and the environmental impact of frequent equipment replacement.

Cost-Effective: Lower operating costs and reduced energy usage contribute to economic sustainability.

Process Efficiency: Speed up production processes while maintaining energy efficiency.

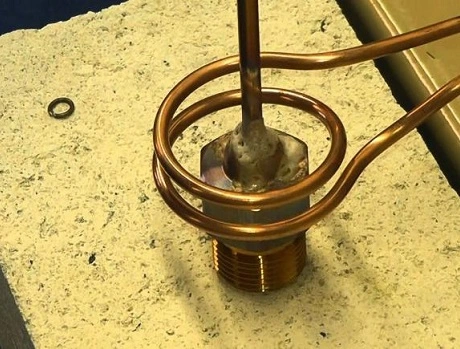

Induction heating, compared to traditional heating methods, has distinctive advantages and features. As a non-contact heating technique, it uses the principle of electromagnetic induction to generate eddy currents within the metal workpiece, achieving rapid and uniform heating. This method offers extremely high thermal efficiency and heating speed, capable of reaching high temperatures within seconds, with precise temperature control that adapts to automated production needs.

Induction heating is environmentally friendly, producing no combustion waste or harmful gas emissions, thus reducing environmental pollution. Moreover, induction heating can optimize the heating process by adjusting the frequency for different depths of heating and workpiece shapes. In contrast, traditional heating methods such as resistance heating and arc heating may have issues like lower thermal efficiency, imprecise temperature control, and environmental pollution.

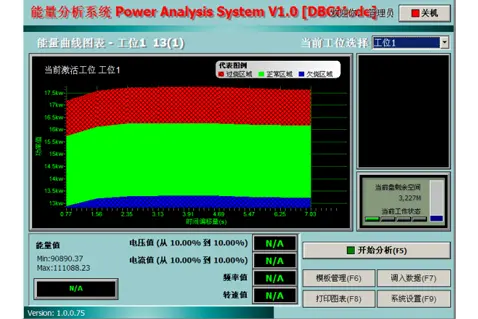

Digital Intelligent Control: Offers superior stability across environments and optimizes IGBT performance for minimal switching loss and temperature impact, preventing efficiency decrease and reducing maintenance costs.

Ultra High Precision Control: Utilizes advanced algorithms for precise frequency control without loss or drift, ensuring nS-level accuracy and optimal power factor through real-time load matching.

Intelligent Protection: Equipped with comprehensive fault detection and protection circuits that provide alarms for various issues, aiding in quick diagnosis and preventing damage.

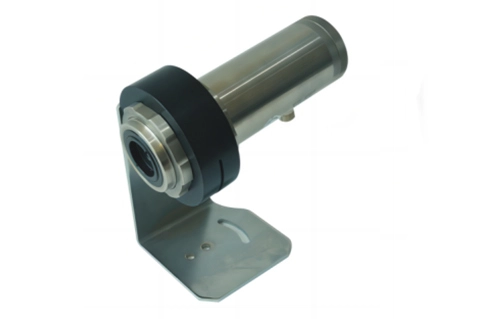

Seal Protection: Features high-grade sealing to achieve IP54 protection, preventing dust, moisture, and soot ingress, ensuring long-term reliability even in harsh conditions.

Providing details of your workpiece is essential initially because it allows for the precise tailoring of the induction heating process to the specific characteristics of the material and shape being heated. This ensures optimal heating efficiency, accuracy, and quality outcomes, while also facilitating the selection of the appropriate equipment and settings for the job.

Material Type: The specific metal or alloy being heated, as different materials have different heating characteristics.

Dimensions: Exact size, including length, width, thickness, and any relevant geometric features.

Shape: The form of the workpiece, including any irregularities or complex geometries.

Tolerances: Required precision levels for the heated area and overall dimensions.

Desired Temperature: The specific temperature range needed for the heating process.

Heat Treatment Goals: Whether the goal is hardening, annealing, normalizing, or another specific heat treatment.

Production Volume: The quantity of workpieces to be heated, affecting the choice of equipment size and capacity.

Surface Condition: The current state of the workpiece surface, including any coatings or finishes.

Mechanical Properties: Required changes in mechanical properties post-heating, such as hardness or ductility.

Special Requirements: Any unique specifications or constraints related to the heating process.

Previous Heating Methods: If applicable, details of any existing heating methods or issues encountered.

Safety and Environmental Considerations: Any specific safety or environmental factors that must be considered.